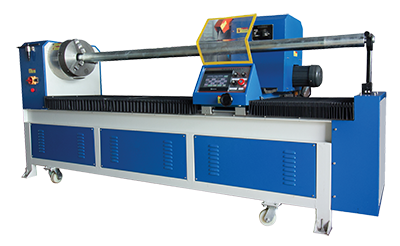

§ Each section individually adjusts the control conveyor so that the fabric is fed without tension.

§ fabric is humid and vapor vibrator relaxation, will make the fabric fully softened.

§ cloth after two steam wet zone, two vibration zone directly into the drying zone, so that the wet fabric can be quickly dried at the best temperature.

§ Adopt strong air cooling system, rapid cooling fabric, the use of temperature difference to achieve the effect of fabric stereotypes.

§ rocker swing the fabric folded back and forth, reducing the tension generated by the cloth.

§ special heating aids, can make up for the lack of steam heating, drying area to adjust the temperature.

§ Standard assembly of the coder can accurately measure the length of the fabric after the finalization.

|

model

|

HS-1800L

|

| Voltage |

3P220V-380V |

| Pressure |

0.5-0.7Mpa |

| Consume steam |

200kg / hr |

| Shrink width |

1800mm |

| Total power |

25.5KW |

| Cooling motor |

0.75KW * 5 |

| Main motor |

0.4KW |

| Conveyor belt motor |

0.2KW * 2 |

| Cloth motor |

90W |

| Shock motor |

90W * 2 |

| Correction motor |

6W * 2 |

| heating power |

20.4KW |

| Belt speed |

0-10m / min |

| Machine size |

6653x2500x2100mm |

| Net / gross weight |

3150 / 3700kgs |